Smart Inventory Management Guide: Everything You Need to Know

Businesses using the right software tools, like custom-made smart inventory management systems, can’t only circumvent issues but also make the processes a breeze. But understanding when you actually need the solution and how to get it built needs a guide.

Are you a business owner or manager? Then, who would know better than you how maddening it is to keep track of Inventory in an organization? Thanks to smart inventory management software, that has made things easier than ever before. In this article, we’re to learn everything about smart inventory management systems.

Keeping track of your Inventory is really antagonizing, and if you’re a business owner or manager, there’s no need to explain it— you’re likely to know it better than anyone else. Inventory management manually is time-consuming, tiresome, and prone to human errors. But it’s no longer the issue; when you have the right tools and technologies, it’s no longer a big deal.

Businesses using the right software tools, like custom-made smart inventory management systems can’t only circumvent issues but also make the processes a breeze. However, it is important to know when you really need a custom solution. The system makes inventory management operations way easier and assists you in streamlining the way you manage Inventory in your company.

Codzgarage is the leading IT firm in the USA, offering reliable and cost-effective services to the client worldwide.Contact us todayand get a free quote.

Inventory management software, however, is undoubtedly a great resource for inventory management; to leverage its full potential, you need to know about it. We’re going to take you through this informative guide containing every single detail about inventory management software so that you gather information and leverage this system to manage Inventory with ease.

Let’s keep an eagle eye on ’em!

Definition of Inventory Management

As per the most common definition, the term Inventory refers to all merchandise and goods a business owns for sale in the market intending to earn profit. For instance, when a newspaper vendor makes use of a vehicle, bike, or any other means of transportation to deliver newspapers to the readers, in that case, not the vehicle or other things but only the newspaper would be considered an inventory.

Now, the Inventory is clear to you, isn’t it? Then, let’s come to inventory management! Inventory management is a significant ingredient of the supply chain. It’s the process consisting of the tracking of inventory right from manufacturers to warehouses, facilities, and sales points. The preliminary purpose of inventory management is to circumvent keeping things at sixes and sevens by having them organized in the right place.

Stats and Facts About Inventory Management

After having a brief glance at Inventory management, let’s move further and learn some stats and facts about inventory management.

- Inventory, accounts payable, and account receivable has tied up to $1.1 trillion in assets. It’s around 7% of the USA’s total GDP.

- Retailers in the USA carry around $1.43 in Inventory for each $1 of sales.

- One of the top ten reasons startups fall is that they don’t manage their Inventory.

- Around 75% of supply chain management professionals tend to enhance their current inventory management practices.

Besides,

- Somewhere around 54% of organizations are planning to expand their warehouses to extend the number of inventory stock-keeping units within the next five years.

Importance of Inventory Management

Irrespective of the size and industry vertical, Inventory is one of the crucial assets in a company. This is where the elements of the supply chain are kept securely. An inventory management system is a crucial ingredient that a business must have. It enables businesses to keep an eye on their supply chain and determine an accurate price.

The system further is able to assist you in managing sudden alterations in product demand without influencing the quality or customer experience. Inventory management is of utmost significance, especially for brands that tend to be more customer-oriented.

Challenges in Inventory Management

As we have known the basics of Inventory management, including inventory management, stats, and facts, and the importance of the same, now let’s come to know the challenges associated with inventory management. Following are some of the inventory management challenges.

- Restricted visibility to Inventory

- Incompetent inventory management procedure

- Recognizing incorrectly located stuff

- Identifying obsolete stocks

- Obstacles with tracking materials

- Insufficiency of centralized inventory hub

- Defects and waste

Types of Inventory

Now, let’s come to know the types of Inventory!

Raw Materials Inventory

In a company, raw materials are all the items that go through multiple processes to create a final product. For instance, in a cookie manufacturing company, the raw materials, including flour, sugar, and milk, are utilized in various stages to yield cookies. Here, you must know that the concept of raw materials as Inventory happens to be merely in the manufacturing industry. As there’s no manufacturing and processing involved in the trending industry, so there’s no concept of raw material there.

Work-In-Progress Inventory

When the raw materials are sent to process, but the final products are yet to get yield, it is considered a work-in-progress stage. When it comes to the cookie manufacturing company, once the raw materials get processed, and cookies get molded, they are sent for quality checks before getting passed for final packaging. Cookies that are yet to be tested for quality are considered a work in progress. To put it in a nutshell, the work-in-progress Inventory is when items are under process but not yet ready to market.

Finished Goods Inventory

Now, let’s know the finished goods inventory. This is when the products are ready for getting sold in the market. These types of goods are passed through all the proceedings like quality checkings and all. For a cookie manufacturing company, the final cookies that are ready to market after quality checks would be the finished items. Raw materials, semi-finished items, and finished items are the three types of Inventory that are accounted for in a manufacturing company’s financial accounts.

Cycle Inventory

Cycle inventory consists of the items which are ordered in lot sizes on a constant basis. Cycle inventory is the material that’s made use of in the production, or they are associated as a part of some consistent procedure.

The Benefits of Smart Inventory Management

After knowing most of the facets of inventory management, we should now have a look at the benefits of smart inventory management. Let’s do that without further ado!

Automation

Automation can be one of the considerable benefits of smart inventory management software. It provides means that allow you to automate manual tasks, for instance, item tracking and counting, restocking, report generation, and so on. It saves time and effort and mitigates human errors.

Inventory Optimization

A smart inventory system identifies the stockouts as well as overstocks and assists you in keeping an adequate amount of Inventory, and launches a just-in-time inventory strategy to lessen the warehouse expense.

Real-time Inventory Visibility

Using a smart inventory management system allows real-time updates on products and status, along with their quantity, location, and movement. It, then, allows managers to have expanded inventory visibility and make accurate, more informed decisions.

Increased Customer Satisfaction

Enhanced customer experience is another aspect that makes smart inventory management essential for businesses. Customer-oriented and efficacious order management, shipments on time, and analytics-driven planning to eliminate overselling and make sure stock availability are what assist you in forming a reputation as a reputed business with your customers.

Identification of Supply Chain Disruptions

With a smart inventory management system, you can have real-time monitoring of warehouse operations that assists you in identifying supply chain disruptions when they occur without any delay. It allows you to take action accordingly. If there’s any disruption pattern, it can be analyzed in no time to recognize the bottleneck and make adjustments essential to the stocking procedure.

Strategies for Smart Inventory Management

Strategic inventory management is a challenge for most companies out there. Employ the following techniques given below for smart inventory management.

Consider Using ERP Software Designed for Inventory Management

There are organizations that make use of spreadsheets for inventory management, but as they scale, they’re likely to switch to basic inventory management software. This system enables them to keep track of their goods effortlessly. Upgrading to an ERP software solution would be even more advantageous— as it enables them to manage supply chains and other processes using a single system.

Optimize Inventory Management by Making Use of Real-Time Data & Analytics

When you have access to real-time data inventory and advanced analytical capabilities, you’ll be able to optimize your inventory management experience in the following ways_

- Enhance customer service with excellent availability of product information.

- Lessen the discounting and scrapping of old items so that you can boost profit margins.

- Anticipate the feasible inventory quantities needed to meet market requirements in the future.

Automate the Inventory Management System in Your Company

Counting stocks can be maddening, time-consuming, and prone to human errors. Inaccuracy in management wouldn’t only cause a loss financially but also result in a deteriorating customer experience. On the other hand, time is the most valuable asset, especially for small companies, and if the management system is automated, you’d be able to save time and utilize them conducting other operations.

An ERP system, like simple inventory management software, conveniently updates inventory levels automatically where stock is dispatched and received; hence, it keeps stock counts updated. When you have all your relevant sales and purchasing order in a single system, you’ll be likely to simply circumvent the stockouts and overstacks. To automate your inventory management, you can add more technologies like:

- Adding barcode scanning allows you to track incoming Inventory flawlessly in no time. This system enables you to accelerate inventory management and offers real-time information regarding sales and stock.

- With a Radio Frequency Identification (RFID) system, you can automate warehouse control, which is ideal for those businesses that need to handle large volumes of orders day in and day out. RFID mitigates the time and efforts associated with manual tracking, hence, resulting in enhanced accuracy and efficiency.

Leverage Demand Planning Tools to Anticipate Future Demands

Inventory management ERP solutions come embedded with forecasting tools you can utilize to predict data of future requirements. The system makes use of data from the past and anticipates the future requirements. Accurate anticipation of future requirements enables you to make a strategy and market your product more efficiently to specific customers.

An ERP system can assist your product sales teams in coordinating with the marketing teams and running advertising campaigns for in-stock products that have high demand in the marketplace. In this way, you’ll be likely to make sure you have the availability of appropriate stocks to extinguish the demands generated by the ad campaigns.

Tools for Smart Inventory Management

Inventory Management Software

Fully-Customized Inventory Management Software Solutions are the perfect tools available for better inventory management. Businesses across the world can utilize these solutions to manage Inventory in companies irrespective of their industry domain.

Barcoding and RFID technology

The implementation of a barcode allows you to keep track of incoming Inventory with no hassles timelessly. The system lets businesses skyrocket the inventory management procedure while providing real-time information about stock and sales. Furthermore, the Radio Frequency Identification (RFID) system enables you to automate the wirehouse control essential for large businesses in need of handling a wide array of orders continuously.

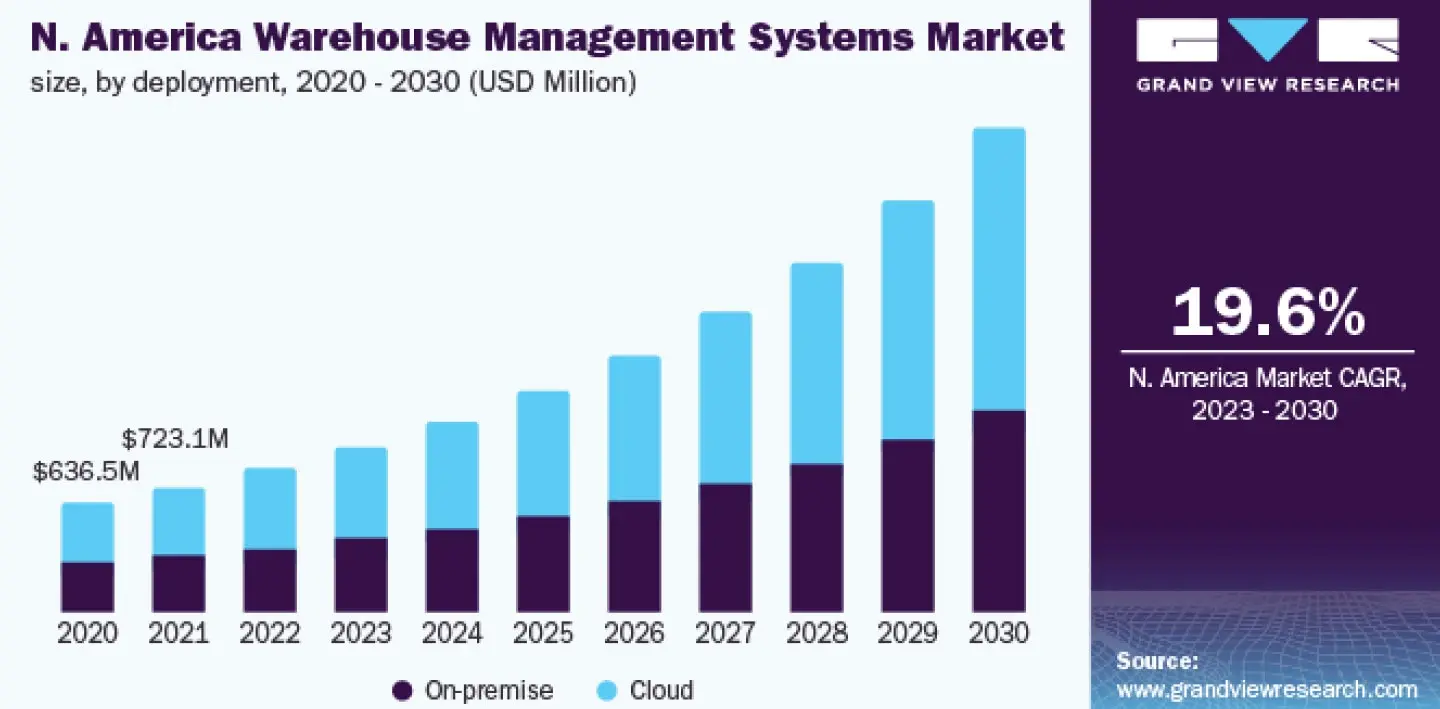

Cloud-based inventory management

The other one we have is a cloud-based inventory management system. It involves monitoring and maintaining a business’s inventory levels and making use of online software solutions. When you employ a cloud-based inventory management system, you can be assured of a seamless track of Inventory in your wirehouses. The real-time updates provided by cloud-based systems allow you to circumvent numerous issues caused by traditional methods of measuring stock levels.

Key Metrics for Inventory Management

Stock Turnover Rate

Stock turnover rate is also known as inventory turn or inventory turnover ratio. It’s the number of times an organization sells and replaces its stock in a certain period, in general, one year. A business can utilize inventory rate to gauge how well a company sells its products from Inventory.

Carrying Cost of Inventory

Inventory carrying cost, aka the cost of carrying Inventory, or holding cost, is the percentage of the whole value a company spends on maintaining Inventory in storage. This cost involves insurance, rent, labor, warehouse management, and any unsellable products. This cost depends on the products a company carries, the storage location, the number of SKUs, the inventory turnover rate, and so on. Besides, it also depends on whether or not a company utilizes a third-party fulfillment company.

Gross Profit Margin

It’s the portion of the selling price that’s gross profit. The metric describes the profit level. You can calculate the gross margin percent using this formula.

Gross margin percent = [(total revenue – the cost of goods sold) / total revenue] x 100

Order Cycle Time

Order timeline or order cycle time is the time taken by a company to fulfill a customer’s order. It shows how well a particular company meets its customer’s demands, for instance, shipping readiness, shipping & delivery. You can utilize this formula to calculate order cycle time.

Order cycle time = (time customer received order – time customer placed order) / # total shipped orders

Best Practices for Inventory Management

Last but not the least! Let’s come to know the best practices for inventory management!

Accurate Forecasting

Accurate forecasting for demands assists you in anticipating all your inventory requirements. You should gauge your orders and identify the low as well as the peak periods of product demands. Assess sales data to determine your best as well as worst sellers and balance your stock. You can make use of social media to conduct surveys and Google Trends to measure current customer trends and utilize the result to accurately predict demand.

Regular Inventory Audits

To embrace a better result, you’ll be required to set up an efficacious internal counting cycle and audit your Inventory on a regular basis. Ensure what you have on the surface conveniently corresponds with what’s in the system. Besides, make investments in additional consultants. When you have specialists, they are prone to unleash the hidden obstacles in your system, provide you with significant ideas and keep you updated about the latest inventory management technology.

Manage Your Obsolete Stocks

Keeping obsolete stocks will be likely to eat into your profits in no time. Follow the way to deal with this. When handling aging stocks, sell-through prices and weekly supplies can be handy metrics. Count all of them to prevent yourself from not being stuck with obsolete stocks, wasting space, and tying up cash in those outdated inventories.

You can mark down all the aging stock and sell it as soon as possible so that you can free up more space and get the cash free to buy new products. You can donate the price to the community as well so that you can market your brand.

Conclusion

Businesses across the world have now become aware of the needs and significance of smart inventory management systems. Inventory management is crucial for any company for better outcomes on their investments. It streamlines business operations, enhances efficiency, and boosts customer experience.

Industry leaders worldwide have embarked on utilizing inventory management tools to gain precise insights into their inventory levels, optimize supply chain procedures, and mitigate dependence and the need for manual labor while skyrocketing the inventory workflows.

Having known about the simple inventory management software might have awakened your interest in this system, mightn’t you? It isn’t a big deal! We at Codzgarage are the one-stop ERP software development company for creating inventory management systems for businesses of all sizes. So, why wait? Meet our experts and get your smart inventory management software built in a heartbeat.

Want to

Hire Fullstack DevelopersOur Expertise

- Skilled backend/frontend

- 11+ years of experience

- Vetted resources

Kevin Bhut

Kevin Bhut